Earthships

Earthships

Michael Reynolds is the creator of Earthships and founder of Earthship Biotecture. Click here to go to Earthships official website.

Cost Effective

The main material costs are relatively inexpensive and sometimes even free when found on site. This combined with doing it yourself makes it very affordable.

Easy To Build

The techniques can be taught fairly easily to helpers. The structure goes up quickly with everyone pitching in.

Do It Yourself

You can do the work yourself with guidance from an experienced craftsman. Friends and family can pitch in to get it done quickly.

Benefits, Costs, and Environmental Impact

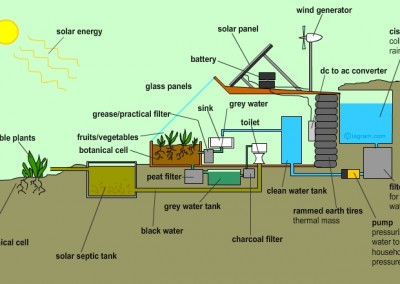

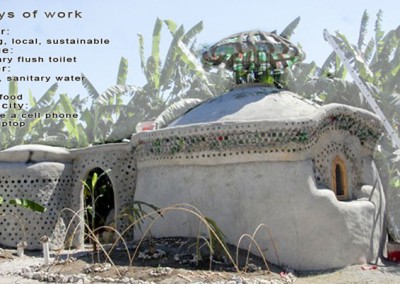

An Earthship is a type of passive solar house that is made of both natural and recycled materials (such as earth-filled tires), designed and marketed by Earthship Biotecture of Taos, New Mexico. The term is a registered trademark of Michael Reynolds, founder of Earthship Biotecture. Click here to go to Earthships official website.

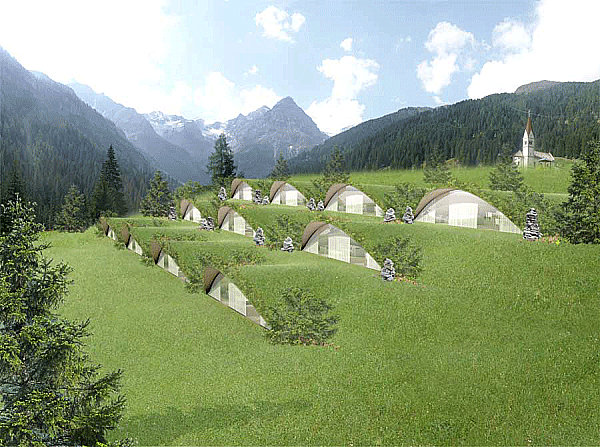

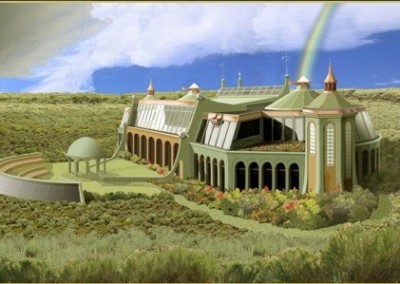

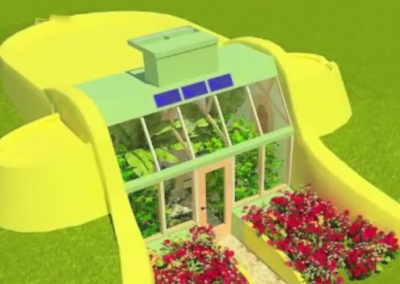

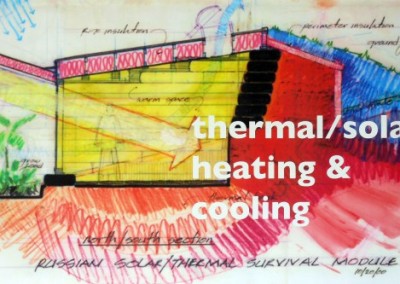

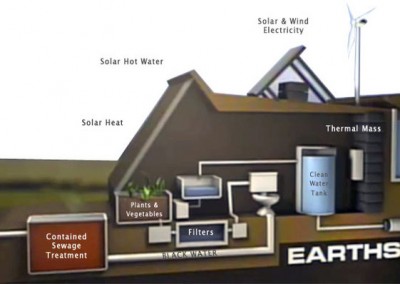

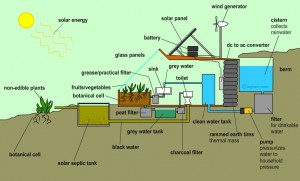

Earthships are intended to be “off-the-grid ready” homes, with minimal reliance on both public utilities and fossil fuels. Earthships are constructed to use available natural resources, especially energy from the sun. Earthships are designed to use thermal mass construction and natural cross ventilation, assisted by thermal draught (Stack effect), to regulate indoor temperature.

Construction Technique

Construction Technique

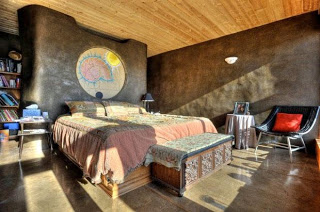

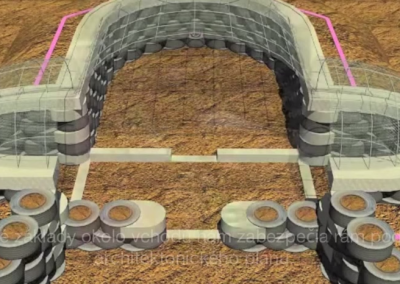

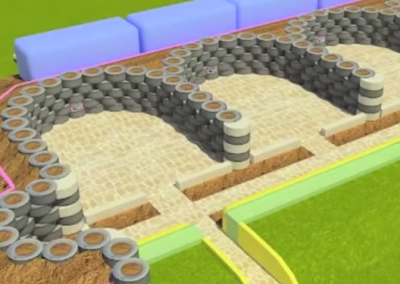

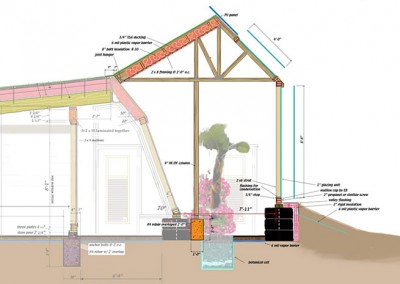

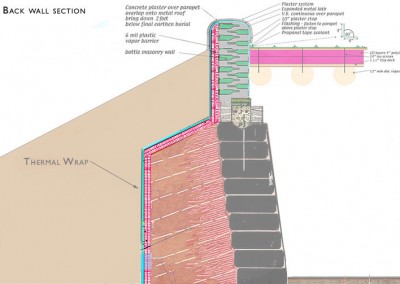

The buildings are often horseshoe-shaped to maximize natural light and solar-gain during winter months, with windows on sun-facing walls admitting light and heat. The thick and dense walls provide thermal mass that naturally regulates the interior temperature during both cold and hot outside temperatures. The outer walls in the majority of Earthships are made of earth-rammed tires, but any dense material with a potential to store heat, such as concrete, adobe, earth bags, or stone, could theoretically be used to create a building similar to an Earthship. The tire walls are strengthened by using concrete in the tires on the ends, called “concrete half blocks”.

On top of the tire walls are either “can and concrete bond beams” made of recycled cans joined by concrete, or wooden bond beams with wooden shoes. These are attached to the tire walls using concrete anchors, poured blocks of concrete located inside the top tires. Wooden shimming blocks placed on top of the wooden bond beam make up the wooden shoes. The wooden bond beam two layers of lumber bolted on to the concrete anchors. Re-bar is used to “nail” the wooden shoes to the wooden bond beam.

Internal, non-load-bearing walls are often made of a honeycomb of recycled cans joined by concrete and are referred to as tin can walls. These walls are usually thickly plastered with adobe.

The roof is made using trusses, or wooden support beams called vigas, that rest on the wooden shoes or the tin can walls placed on the bond beams. The roof as well as the north, east and west facing walls are heavily insulated to prevent heat loss.

Websites and Videos

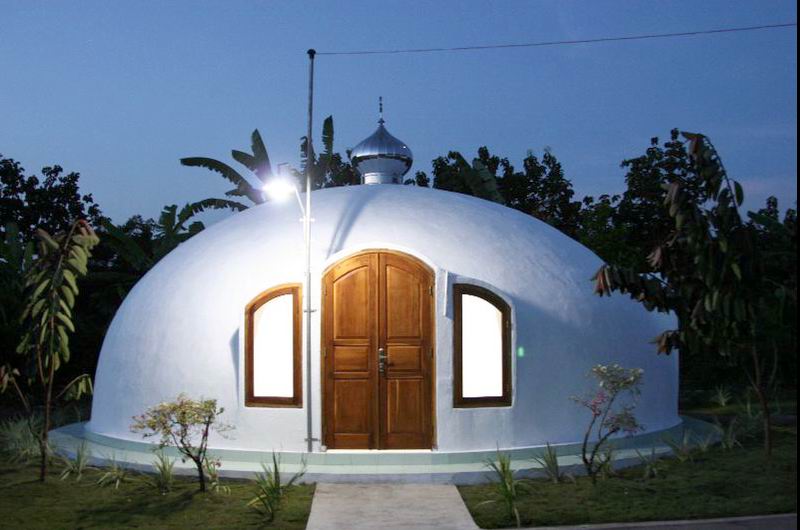

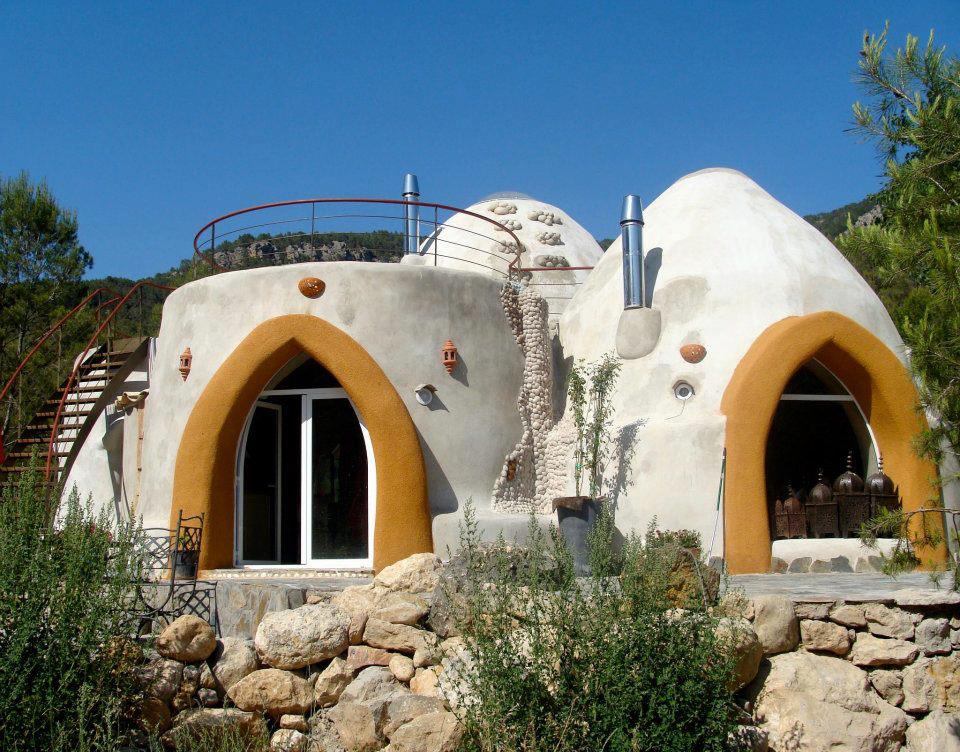

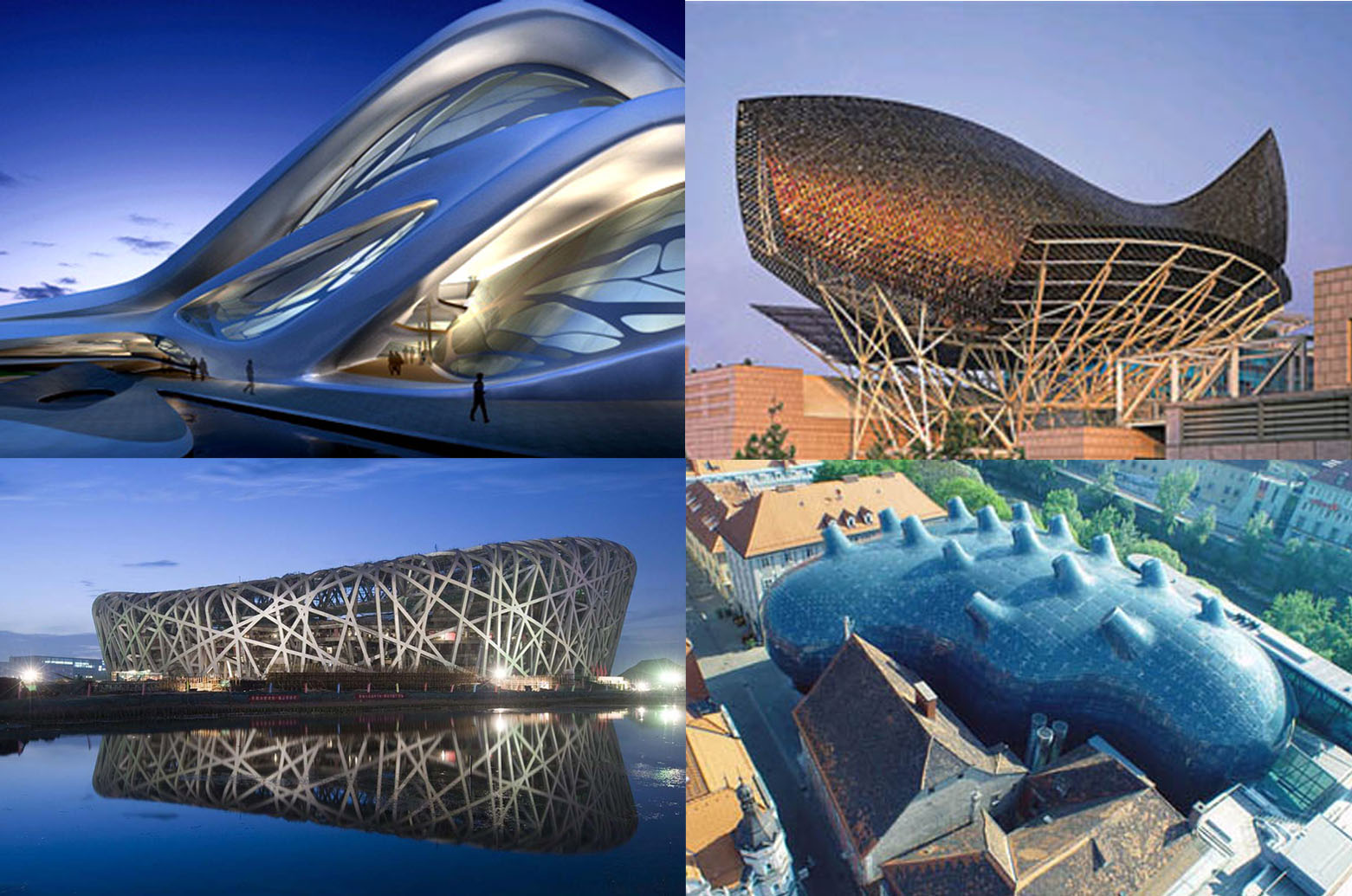

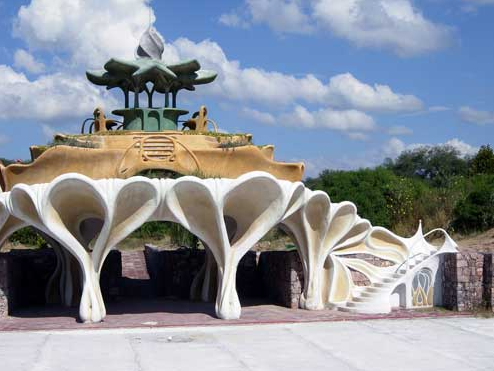

Click Image Below See More Sustainable Building Types